CO2 Laser Processing

Technology

Carbon dioxide (CO2) lasers are high-powered continuous-wave lasers used for a range of applications such as scribing, machining, drilling, and skiving. Our CO2 processing offers the most efficient way to produce highly accurate and intricate parts without expensive tooling.

ALT’s technicians have customized our CO2 lasers to produce the best quality beam. With our current configuration we’ve eliminated inconsistencies that can occur with standard laser systems received from laser manufacturers.

Support

One advantage of using ALT is our ability to provide several support processes for CO2 lasering. These vital tools supplement and enhance the quality of products our customers receive. Such tools include:

For your convenience, CAD files can be translated directly into machine code limiting possible operator errors normally involved with data entry. Our pre-processing of incoming material minimizes the attachment of laser generated residue to the substrate surface, protecting against surface abrasions during handling. ALT offers post processing of materials that can often times require the aid of optical cameras. With our high powered cameras, we are capable of holding +/- .001 inch from the outside edge of any metallized circuit. We have developed several profiles for various applications of high temperature annealing. In general, high temperature annealing relieves stress in the alumina and allows for better adhesion of conductor and resistor ink. Post process ball milling is also available. Substrates of various materials can be safely milled to smooth outer edges, facilitating edge metallization.

Materials

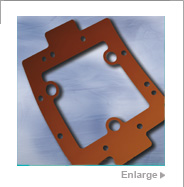

Soft materials used for gaskets and insulators: Rubber, Vinyl, Teflon, Polyimide, Duroid

Flex Circuit industry materials: “Kapton”, Adhesives

Epoxy preform materials

Plastics and Polycarbonates

Printed circuit board materials: FR-4, G-10

Metals: Stainless Steel, Cold Rolled Steel, Soft Steel

Beryllium

Alumina based ceramics – 91% opaque, 96% and 99.6%

High & Low transfer tape

High thermally conductive compositions of Beryllium Oxide and Aluminum Nitride

High dielectric constant materials: Sapphire, Quartz and Fused Silica

If you have a material not listed, please let us know and we’ll be happy to process a sample for your evaluation.